- 浙江煜豐機床有限公司

- 400-101-9515

- 17038692683@www.jinboce.com

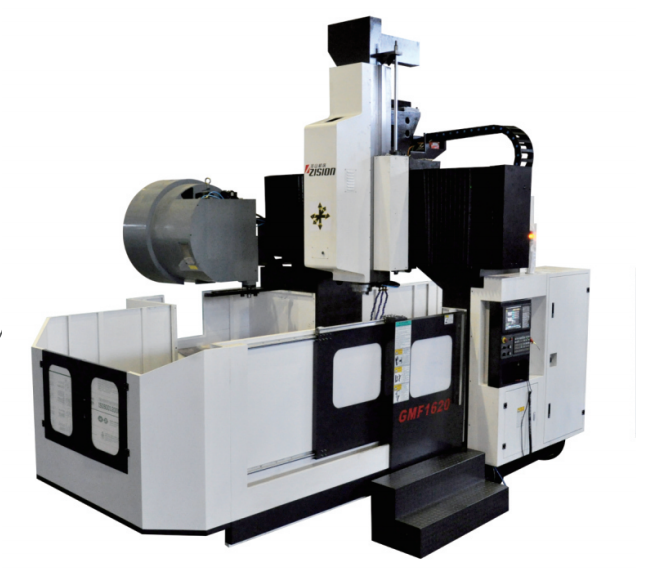

採用熱對稱性優異的龍門框架式結(jie)構,整體門框是-體鑄造而成的,防(fang)振能力大大提(ti)升。

床身、龍門框架、滑(hua)鞍、工作壹等關鍵(jian)零件均採用樹(shu)脂砂造型,高強度鑄鐵,穩定性好。

設計上加大內三角支撐,主軸在橫樑.上運行振動更小,減小橫樑變(bian)形,更能保證表面粗糙度質(zhi)量。

X、Y軸採用重(zhong)載滾柱錢軌,剛性強、動態精度佳。

三軸傳動採用基灣產大直徑研(yan)磨雙螺母滾珠絲杆,結(jie)構緊湊、運動平穩、精度高。

橫樑採用階梯式結(jie)構,橫樑截面大,導軌跨距(ju)大,主軸中心到導軌面距(ju)離段,翻轉力矩小,結(jie)構剛性好。

High- rigidity double column, once-shaping column and beam, fully prop up slidewaym, to support quakeproof.

Bed, columen, carriage, table use phenolic sand molding, high sthength casting iron, good stablity.

Extra-large triangular prop up, spindle shake less, reduce beam taansformation, support surface roughness quality

X, Y axis use roller guide way, high rigidity and good dynamic precision.

3 axis use double nut lea screw, compact structure, smooth motion, high precision.

Ladder type beam, big section, large distance between guide ways, short distance between spindle center to

guide way, small tilting force, high rigidity.

| 項 目 | Specification | 單位 Unit | GMF1610 | GMF1620 | GMF1630 | |

|

|

mm | 1500x 900 | 2000x1300 | 3000x 1300 | ||

| 工作薹承重(zhong) | Max loading weight | Kg | 3500 | 5500 | 8000 | |

| T型槽(槽數×槽竟×節距(ju)) T-slot | mm | 5-22×190 | 7-22x180 | 7-22x180 | ||

| X軸行程 | X travel | mm | 1000 | 2200 | 3200 | |

| Y軸行程 | Y travel | mm | 1500 | 1500 | 1500 | |

| Z軸行程 | Z travel | mm | 800 | 800 | 800 | |

| 龍門跨距(ju) | Distance between two column | mm | 1600 | 1600 | 1600 | |

| 主軸端面至工作薹 | From table to spindle nose | mm | 200-1000 | 200-1000 | 200-1000 | |

| 主軸維孔 | Spindle bore | BT50 | BT50 | BT50 | ||

| 主電機功率 | Main motor | KW | 15/18.5 | 15/18.5 | 15/18.5 | |

| 主軸轉速 | Spindle speed | rpm | 6000 | 6000 | u… 6000 | |

| X/Y/Z尊軌型式 | 3 axis quide way | X/Y/Z軸滾柱線軌,Z軸硬軌 | ||||

| 三軸伺服電機扭矩 | 3 axis servo motor torqueXY/Z | N.m | 40/30/30 | 40/30/30 | 40/30/30 | |

| 快速誰給X/Y/Z | Ripid XYZ | m/min | 15/15/12 | 15/15/12 | 15/15/12 | |

| 切削迪給 | Feed | mm/min | 1-8000 | 1-8000 | 1-8000 | |

| 定位精度 | Positional accuracy | mm | 0.018/0.016/0.015 | 0.018/0.016/0.015 | 0.024/0.016/0.015 | |

| 重(zhong)後定位精度 | e-positional accuracy | mm | 0.010/0.009/0.008 | 0.010/0.00/0.008 | 0.012/0.009/0.008 | |

| 刀(dao)具數量 | Tool magazine | 把 | 24圓搖式(32/40鍵(jian)式) | |||

| 刀(dao)具最大長度/重(zhong)量 | Tool max lengthweight | mm/kg | 300/15(25) | |||

| 刀(dao)具最大直徑(滿刀(dao)/臨刀(dao)) Tool max dia. (ulladjacent empty) | mm | Φ110/Φ200(Φ125/Φ245) | ||||

| 刀(dao)具交換時(shi)間(刀(dao)-刀(dao)) | Tool-to-tool | s | 3 | |||

| 佔地面蹟(長x竟) | Leng x width uu | mm | 3500× 3700 | 6340×4000 | 8300× 4000 | |

| 機床高度 | Height | mm | 4300 | 4300 | 4300 | |

| 整機估重(zhong) | Weight | T | 15 | 21 | 25 | |

本公司對產品規格、設計特性均不斷研(yan)究改進,上述技術參數等若有變(bian)更,恕不另行通知。

The company s product specifications,design features are constantly studying to improve, Technical parameters such as the above are subject to change without notice.